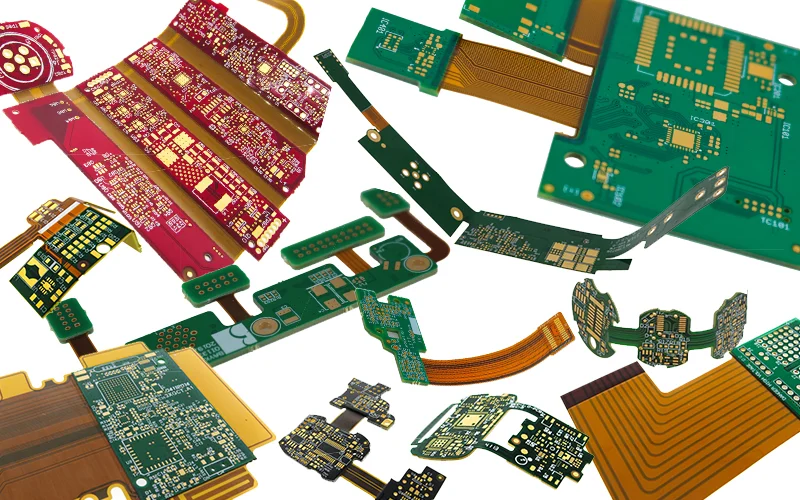

The flexible printed circuit board is a type of circuit board that is made up of “Flexible Printing Circuit Board”a thin layer of copper foil that is attached to a plastic film. This type of circuit board is used in a variety of electronic devices, including smartphones and tablets. One of the main benefits of using a flexible printed circuit board is that it can be bent and curved to fit the contours of the device. However, if the board is mishandled or damaged, it can cause a number of problems for the device. In this article, we will discuss how to avoid damage to the flexible printed circuit board.

1) What is a flexible printing circuit board?

Flexible printed circuit boards (FPCBs) are used in a wide range of electronic devices and have many advantages over traditional rigid printed circuit boards.

FPCBs are much more flexible and can be bent or folded to fit into smaller spaces. This makes them ideal for use in portable electronic devices such as laptops, mobile phones and MP3 players.

FPCBs are also much lighter than rigid printed circuit boards, which makes them ideal for use in aircraft and satellites where weight is a major consideration.

Another advantage of FPCBs is that they can be manufactured using a variety of different materials, including plastic and metal. This makes them much more resistant to heat and electrical damage than traditional printed circuit boards.

Finally, FPCBs can be manufactured using a variety of different printing processes, including screen printing, direct-write and laser-based methods. This allows for a high degree of customization and allows manufacturers to produce FPCBs with a wide range of different designs.

2) What are the benefits of using a flexible printing circuit board?

Flexible printing circuit boards offer many benefits over traditional rigid boards. They are lighter weight, more durable, and more resistant to shock and vibration. They can also be bent or rolled to fit into tight spaces.

Flexible boards are also easier to work with and require less specialized equipment. They can be cut with a knife or scissors, and the circuits can be printed directly onto the board with a desktop printer.

There are a few drawbacks to flexible boards, however. They are more expensive than rigid boards, and the circuits are more likely to be damaged if the board is bent too much.

Overall, flexible printing circuit boards offer many advantages over rigid boards. They are lighter, more durable, and easier to work with. If you are looking for a way to save space and reduce weight in your next project, consider using a flexible board.

3) How can you avoid damage to the flexible printing circuit board?

3 Ways to Avoid Damage to the Flexible Printing Circuit Board

1. Use the correct tools

When working with the flexible printing circuit board, it is important to use the correct tools. This will help to avoid any damage to the board.

2. Be careful when handling the board

When handling the board, be careful not to bend or flex it too much. This can damage the board.

3. Store the board properly

When not in use, the flexible printing circuit board should be stored in a dry, clean place.

4) Conclusion

When it comes to choosing the right flexible printed circuit board (PCB) for your project, there are a few things to keep in mind. With so many different types and manufacturers of PCBs on the market, it can be difficult to know where to start. Here are four tips to help you avoid damage to your flexible PCB:

1. Choose the right material for your project.

There are a variety of flexible PCB materials available on the market, each with its own set of advantages and disadvantages. It’s important to choose the material that best suits the needs of your project. For example, if you need a PCB that can withstand extreme temperatures, you’ll need to choose a material that can withstand those temperatures.

2. Choose the right thickness for your project.

Flexible PCBs are available in a variety of thicknesses, from as thin as 0.5mm to as thick as 3mm. The thickness you choose should be based on the needs of your project. If you need a PCB that can be flexed or bent, you’ll need to choose a thinner PCB. If you need a PCB that is more rigid, you’ll need to choose a thicker PCB.

3. Choose the right surface finish for your project.

The surface finish of your PCB can have a significant impact on the performance of your project. There are a variety of surface finishes available, from plated finishes to non-plated finishes. It’s important to choose the surface finish that best suits the needs of your project.

4. Choose the right manufacturer for your project.

Not all PCB manufacturers are created equal. When choosing a PCB manufacturer, it’s important to choose one that has experience manufacturing flexible PCBs. Make sure to ask about the minimum order quantity (MOQ) and lead time for your project.

following these tips will help you avoid damage to your flexible PCB.