Have you ever wondered how laser metal cutting has transformed manufacturing?

This cutting-edge technology delivers precision and efficiency like never before. From aerospace to automotive, industries rely on it for top-quality results.

In this article, we’ll explore the Top 7 Innovations in Laser Metal Cutting Technologies. Discover how these advancements are shaping the future of the industry. Ready to dive in? Let’s get started!

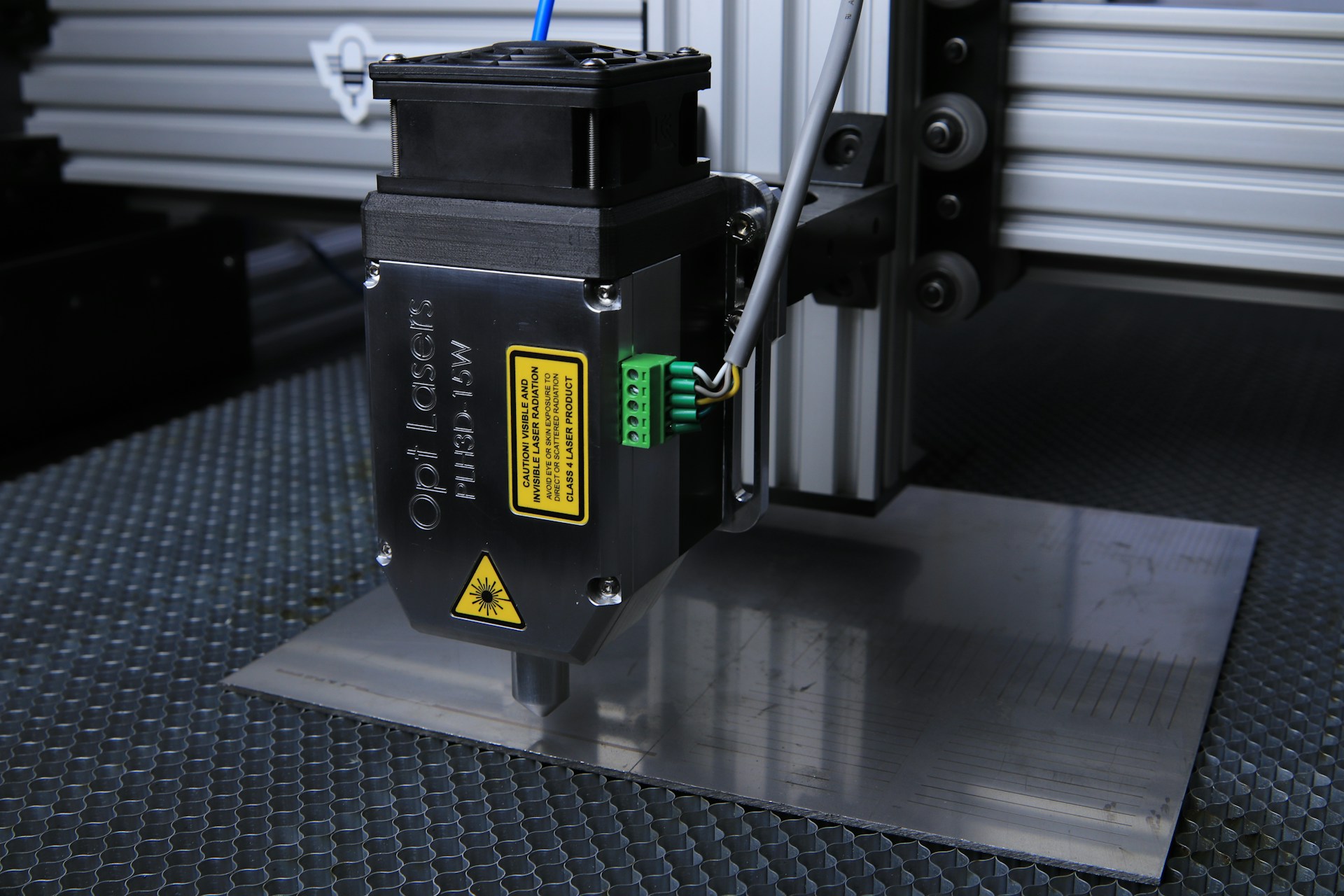

1. Fiber Laser Technology

Fiber laser technology has revolutionized the way we approach metal cutting. It uses a solid-state laser, which produces a high-quality beam with a narrow focus. This allows for precise cuts in various types of metals, making it ideal for intricate designs. A laser cutter for metal offers faster processing speeds and reduces material waste.

2. High-Power Laser Systems

High-power laser systems are changing the landscape of the metal cutting industry. These lasers offer increased energy output. This allows for faster and more efficient cutting. With higher power, metal cutting lasers can handle thicker materials. These are materials that were challenging for older systems. This leads to greater productivity and reduced operating costs for manufacturers.

3. Intelligent Process Monitoring

Intelligent process monitoring is a game-changer in laser metal cutting. This technology uses sensors and software to track the cutting process in real-time. It helps operators identify issues quickly. This allows for immediate adjustments. As a result, the quality of cuts improves significantly. Additionally, it reduces downtime, making operations more efficient and cost-effective.

4. Automation and Robotics

These are playing a crucial role in the evolution of laser metal cutting. By integrating automated systems, manufacturers can achieve higher efficiency. They can also achieve consistency in their operations. Robots can handle repetitive tasks. This frees up human workers to focus on more complex activities.

5. Cutting Software Innovations

Cutting software innovations have improved laser metal cutting processes. These advancements streamline the design and production phases. This makes it easier for operators to create intricate patterns. User-friendly interfaces allow for quick adjustments and modifications to designs. This saves time and resources.

6. Hybrid Laser Technologies

These combine different cutting methods to enhance performance in metal cutting applications. Manufacturers can enjoy the strengths of both technologies. This is by integrating fiber and traditional CO2 lasers. This combination allows for better cut quality. It also allows versatility across a wider range of materials.

7. Eco-Friendly Laser Cutting

Eco-friendly laser cutting is becoming important in today’s manufacturing landscape. Many manufacturers are now looking for ways to reduce their environmental impact. This trend has led to the development of more sustainable practices in the industry. A reliable laser cutting company will focus on using materials. These are less harmful to the environment. Businesses can help conserve resources and promote a greener future. This is by adopting these eco-friendly methods.

All About Laser Metal Cutting Technologies

In conclusion, laser metal cutting is transforming the manufacturing world. This is with its precision and efficiency. The innovations discussed highlight how technology continues to evolve. This makes cutting processes faster and more environmentally friendly.

As industries adopt these advancements, they improve productivity and product quality. Embracing these changes will ensure that businesses stay competitive. This ensures they meet future demands in the realm of laser metal cutting.

Looking for more tips and ideas? We’ve got you covered. Check out some of our other posts now.