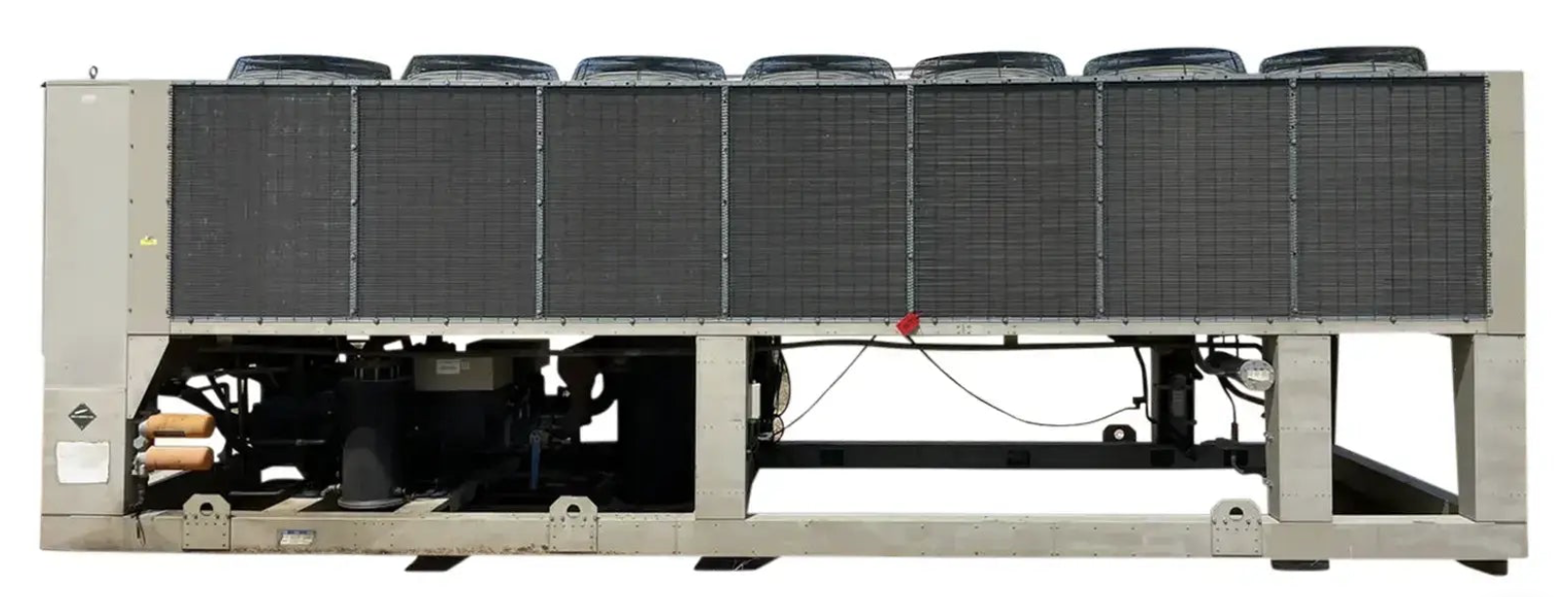

Air cooled condensers are a cornerstone in modern industry, offering an array of advantages from energy savings to environmental benefits. These systems provide critical cooling for machinery, electronics, and processes that generate significant amounts of heat. Understanding their value is pivotal for any business looking to maximize efficiency and reduce operational costs. Keep reading to delve deeper into the benefits that air-cooled condensers bring to the table in industrial settings.

Understanding Air-Cooled Condensers and Their Role in Industrial Cooling Systems

Condensers are vital components in refrigeration and air-conditioning systems, removing heat from the system by changing the state of the refrigerant from gas to liquid. Air-cooled condensers, in particular, use ambient air to achieve the cooling effect, bypassing the need for water which is a crucial resource in evaporative cooling systems. This fundamental difference makes air-cooled systems particularly attractive for areas where water is scarce or expensive.

In industrial settings, these condensers are used to maintain suitable temperatures for equipment or processes that produce heat. By utilizing fans to dissipate heat into the atmosphere, air-cooled condensers efficiently manage thermal loads without reliance on other cooling mediums. This allows for a more flexible and adaptable approach to industrial cooling, as these units can be situated in varied locations, including rooftops or external settings.

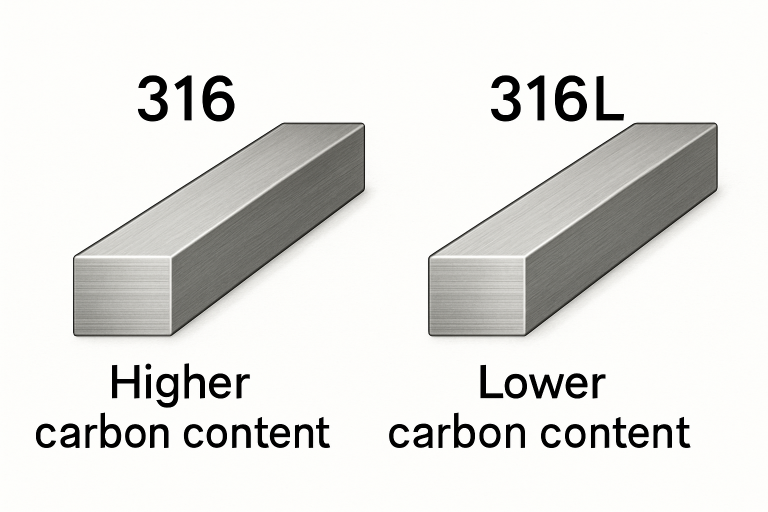

Durability and reliability are key attributes of air-cooled condensers, as these systems are designed to withstand harsh conditions and heavy usage. They often feature robust designs with materials resistant to corrosion and wear, making them well-suited for industrial environments. Additionally, the simplicity of their design often translates to fewer mechanical issues and easier maintenance.

The Impact of Minimal Water Usage on Industrial Operations

Unlike water-cooled systems that require a continual water supply, air-cooled condensers use the ambient air, eliminating the need for water in the heat rejection process. This has a significant impact on industrial operations, particularly in areas experiencing water scarcity or those subject to stringent water use regulations. By conserving water, companies not only uphold environmental stewardship but also ensure their operations are sustainable over the long term.

Reduced water usage also means fewer concerns over water quality and treatment, which can be costly and complex. Air-cooled systems circumvent the issues related to scale buildup, corrosion, and biological growth that are common in water-based cooling systems. This aspect alone can lead to substantial cost savings and a reduction in maintenance efforts, benefiting the overall operational efficiency.

Additionally, the absence of water in the system negates the need for associated infrastructure such as cooling towers, pumps, and treatment facilities. This not only reduces initial investment costs but also lessens the physical footprint of the cooling system, providing more real estate for other essential operations within industrial facilities.

Air Cooled Condensers: A Solution for Challenging Environmental Conditions

Air-cooled condensers offer unmatched versatility when it comes to operation in challenging environmental conditions. They are especially well-suited for hot, dry climates where water resources are limited and the use of air as a cooling medium is most effective. Their design ensures a steadfast operation even when external temperatures are high, ensuring process continuity and preventing overheating.

The resilience of air-cooled systems is not limited to temperature alone. These condensers can be constructed with materials and coatings designed to withstand corrosive environments, salty air, and other industrial pollutants. This contributes to their longevity and consistent performance in settings that would otherwise accelerate the deterioration of less robust cooling systems.

Long-Term Cost Savings and Maintenance Advantages of Air Cooled Systems

The long-term financial benefits of air-cooled condenser systems are substantial. The reduced requirement for maintenance is a key factor in realizing these cost savings. Without the need for constant water treatment, monitoring, and replenishment, companies can reallocate resources to other crucial areas of their operations, enhancing productivity and profitability.

Air-cooled condensers are renowned for their low maintenance demands, thanks mainly to fewer moving parts and the absence of water-related components such as pumps and chillers. Regular inspections and cleaning of the coils and fans are typically sufficient to keep these systems operating at peak efficiency, thus minimizing downtime and extending the lifespan of the equipment.

Overall, the strategic advantage provided by air-cooled condensers in industrial applications cannot be overstated. From the long-term cost benefits and energy savings to the positive environmental impact, these systems present an efficient and sustainable cooling solution. They stand as a testament to innovation in industrial engineering, answering the call of modern industries for reliable, adaptable, and economically sound technology.