Lubrication technology is evolving to meet the demands of modern machinery, which often requires a balance between cost-effictiveness and high performance. Hybrid lubrication systems, which combine the best attributes of traditional and synthetic lubricants, are emerging as a versatile solution. These systems offer manufacturers and industries a way to optimize performance while managing operational costs, making them an increasingly popular choice in diverse applications.

The Basics of Lubrication

Traditional lubricants, typically derived from mineral oils, have long been a staple in industrial and automotive settings due to their affordability and availability. On the other hand, synthetic lubricants, engineered through advanced chemical processes, offer superior performance in extreme conditions but are often more expensive.

Hybrid lubrication systems blend these two types, leveraging the strengths of each to address specific operational challenges while mitigating their individual drawbacks.

How Hybrid Lubrication Systems Work

A hybrid lubrication system typically uses a combination of base oils and additive packages tailored to the application’s needs. Here’s how they strike a balance:

- Base Oil Mix: The system may combine mineral oil for cost-effectiveness with synthetic oil for enhanced thermal stability and oxidation resistance.

- Targeted Additives: Additives such as anti-wear agents, friction modifiers, and corrosion inhibitors are carefully selected to ensure compatibility and performance.

- Custom Formulations: Depending on the application, hybrid lubricants can be tailored to specific machinery requirements, such as temperature ranges, load capacities, or environmental exposure.

Advantages of Hybrid Lubrication Systems

The integration of traditional and synthetic solutions in hybrid lubrication systems offers several key benefits:

- Cost-Effectiveness: By blending mineral oils with synthetic components, hybrid systems provide a more affordable option compared to fully synthetic lubricants while delivering improved performance.

- Versatility: Hybrid systems can be customized for a wide range of applications, from high-speed machinery to heavy-duty equipment operating under extreme loads.

- Enhanced Performance: The inclusion of synthetic components improves resistance to oxidation, thermal breakdown, and viscosity loss, ensuring stable operation over time.

- Environmental Benefits: Hybrid lubricants often use advanced additives to reduce energy consumption and minimize emissions, supporting sustainability goals.

Applications of Hybrid Lubrication Systems

Hybrid systems are particularly well-suited for industries that demand reliability and performance without excessive cost:

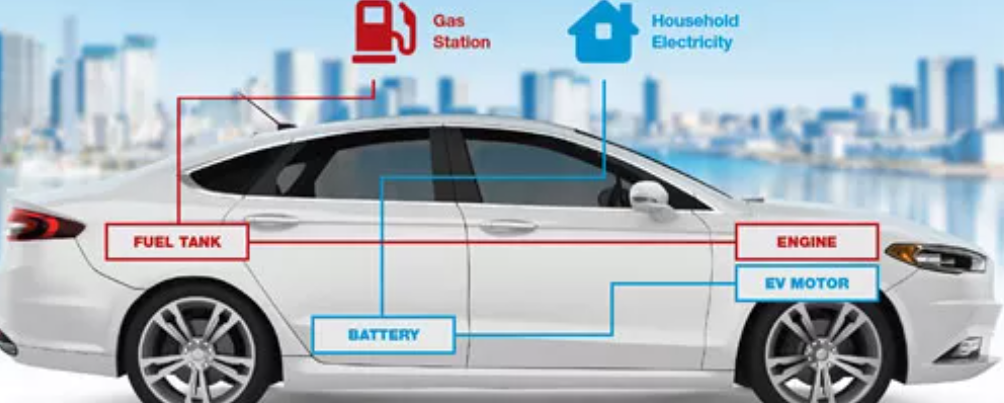

- Automotive: Engines and transmissions benefit from hybrid lubricants’ ability to reduce wear, improve fuel efficiency, and operate across varying temperature ranges.

- Manufacturing: Hybrid lubricants excel in reducing energy consumption and wear in high-load machinery, extending equipment life and lowering maintenance costs.

- Construction and Mining: Heavy-duty equipment operating under extreme conditions relies on hybrid solutions for consistent performance and durability.

Challenges and Considerations

While hybrid lubrication systems offer significant advantages, they are not without challenges. Achieving the right balance of traditional and synthetic components requires precise formulation and rigorous testing. Additionally, compatibility with existing systems and regulatory compliance must be considered during implementation.

The Future of Hybrid Lubrication Systems

As technology advances, hybrid lubrication systems are expected to become even more efficient. Innovations such as nanotechnology-enhanced additives and biodegradable formulations are likely to play a significant role in the evolution of these systems.

Conclusion

Hybrid lubrication systems represent the best of both worlds, combining the affordability of traditional lubricants with the high performance of synthetic options. Their versatility, cost-effectiveness, and ability to address specific operational challenges make them an invaluable tool for modern industries. As demands on machinery continue to grow, hybrid lubrication systems offer a sustainable and efficient path forward, ensuring optimal performance without breaking the budget.