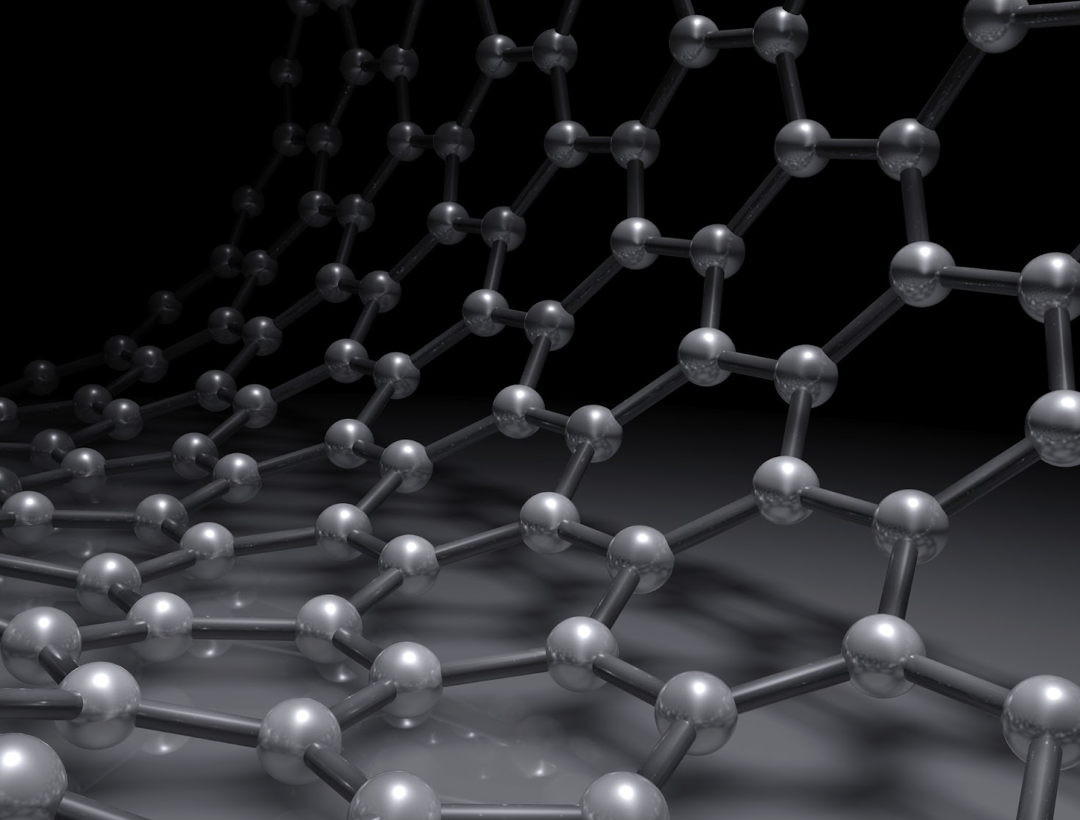

The quest to make devices smaller, faster, and more efficient naturally resulted in continuous innovations in materials and design. Such breakthrough material with huge potential for revolutionizing transistor design is carbon nanotubes. As versatile electronic components, CNTs will go on pushing boundaries on what can be done with semiconductor technology to offer new horizons for the electronics industry. The article is going to take you through the key things you should know about carbon nanotubes and its use in electronics, so continue reading for more.

Why Carbon Nanotubes?

Carbon nanotubes have many properties, and these properties make them highly attractive for electronic applications, especially in transistor design. These properties include the following:

- Electrical Conductivity: CNTs development in ballistic transport enables the electrons to move through it with very little scattering that in turn offers very low resistance in conducting electricity to them. This, therefore, makes them very ideal for high-speed electronic devices.

- Size and Scalability: With their diameters as small as 1 nanometer, CNTs are able to create transistors at a scale much smaller than what is possible in traditional silicon-based technology. This miniaturization is very essential as the electronics industry continually seeks to pack more transistors within a given area in line with Moore’s Law.

- High Carrier Mobility: This is the prime factor that decides the velocity of the charge carriers and in turn, thus affecting the transistor speed. They have high carrier mobility, which implies faster switching speeds and increased performance of electronic devices.

- Thermal Conductivity: They have the ability to conduct heat efficiently—the feature is highly critical in view of the performance and durability of electronic components with the trend of devices getting small and powerful.

Carbon Nanotube Transistors

By today’s standards, transistors are deemed the fundamental building block of any electronic device and basically function as switches or amplifiers in circuits. Integrating CNTs into transistors resulted in the advent of carbon nanotube FETs, also referred to as CNTFETs, that possess some very positive features compared to traditional silicon-based transistors.

Design and Operation

A typical CNTFET consists of a carbon nanotube which connects or bridges the source and drain terminals with a gate terminal controlling the flow of current through the nanotube. The operation of the CNTFET is similar to the conventional field-effect transistor; however, the use of CNTs as the channel material introduces remarkable performance enhancements.

Advantages of CNTFETs

- Higher Performance: Since the electrical properties of CNTs are much better, CNTFETs can act at higher velocities and more efficiently than silicon-based transistors. For these new transistor applications, particularly for mobile devices and high-performance computing, the fastest possible data processing with low power consumption is a very basic requirement, for which performance acts as a key driver.

- Low Power Consumption: Due to its high carrier mobility and low threshold voltage, CNTFETs will consume less power. This is an issue with battery-operated devices where energy efficiency has a huge impact on the lifespan of devices.

- Scalability: Because CNTs are very small, it enables the development of far smaller transistors compared to what was possible with silicon. Further miniaturization in electronics needs this scalability to have more powerful devices within compact physical volumes.

Challenges and Solutions

Though this technology holds huge promise, several challenges need to be addressed before CNTFETs can be accepted by commercial markets.

Manufacturing Uniformity

One of the major challenges associated with CNTFETs is to produce CNTs which have uniform properties and to integrate them into devices in a controlled way. This means that variations in diameter, chirality, and purity can alter the electronic properties of CNTs and result in variability in the performance of CNTFETs.

Solution: Improvements in synthesis techniques, such as chemical vapor deposition, and sorting methods that separate CNTs by type and quality, help to increase the uniformity and scalability of CNT production.

Integration into existing technology

Another challenge to replace silicon transistor technology with CNTFETs is integrating them into semiconductor manufacturing processes. Industry investment in silicon-based technology is huge, hence shifting to CNT would require a lot of change in fabrication techniques and equipment.

Solution: Researchers are exploring hybrid approaches where CNTs collaborate with traditional silicon technology. The hybrid devices will look toward taking advantage of the benefits of the CNT while maintaining a compatible infrastructure.

Contact Resistance

The metal contacts of a CNTFET with the CNT can add considerable resistance that severely impacts the performance of the device.

Solution: Research is in progress for developing better contact materials and fabrication techniques that reduce contact resistance and enhance the efficiency of CNTFETs.

Applications of CNTFETs

The applications of CNTFETs will be broad and diverse, offering solutions to many critical aspects of Electronics and Technology.

High-Performance Computing

They can improve the performance of processors and memory devices, thus allowing computation to be faster and more power-efficient. This is rather important for applications that need intensive processing of data, such as artificial intelligence and machine learning.

Flexible Electronics

The flexibility and strength of CNTs render them rather appropriate to be applied in flexible and wearable electronics. CNTFETs can be fabricated on flexible substrates, thus leading to bendable displays and health monitors wearables, among many other devices.

Low-Power Devices

The low power consumption of the CNTFETs comes very handy in low-power applications like Internet of Things devices, where long battery life is desired.

Transparent Electronics

CNTs can be used to create transparent transistors, which could be useful for a variety of applications, such as transparent displays and solar cells. The transparency, coupled with high electrical conductivity, that CNTs provide opens up a wealth of new opportunities for embedding electronic functionality into a wide range of surfaces or materials.

Future Prospects

Basically, CNTFETs are still at the baby stage of development. Nevertheless, the prospects so far are very promising. Continued research and refining of the manufacturing techniques will no doubt make the integration of CNTs into electronic devices more plausible and widespread. The ability of the CNTFET to revolutionize transistor design and increase the performance expectations for electronic componentry is vast, offering some very exciting possibilities for the future of technology.

Conclusion:

Carbon nanotubes have the potential to be a game-changing material in the field of electronics, offering enormous potential for shifting transistor design and changing boundaries on what can be achieved with semiconductor technology. Excellent electrical, mechanical, and thermal properties make CNTs suitable for the development of high-performance, energy-efficient, and scalable transistors.

While challenges still remain, continuous research and development pave the way for wide adoption of CNTFETs in many applications, from high-performance computing to flexible electronics. With the technology fast maturing, carbon nanotubes are going to hold a very important place in a new generation of electronic components, driving innovation and realizing things previously impossible.