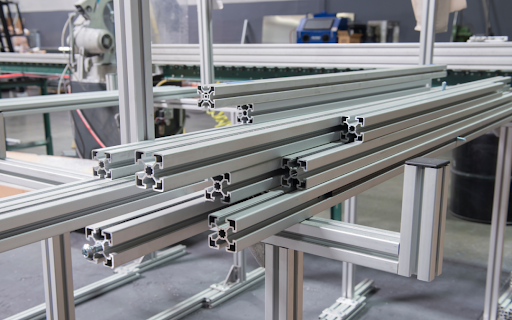

Aluminum expulsion is a cycle that has changed different enterprises by giving a flexible, proficient, and financially savvy strategy for molding aluminum into a great many items. As a material, aluminum is commended for its lightweight, strength, and protection from erosion, making it an optimal decision for various applications. This article digs into the complexities of aluminum expulsion benefits, their advantages, and their broad applications across various areas.

Figuring out Aluminium Expulsion

Aluminum expulsion is an assembling interaction where aluminum compound material is constrained through a pass on with a particular cross-sectional shape. The outcome is a long piece of aluminum with a predictable profile that can be sliced to wanted lengths. This interaction takes into account the production of perplexing shapes that would be troublesome or difficult to accomplish with other assembling methods.

The Expulsion Interaction

Planning: The interaction starts with the choice of a fitting aluminum combination. The picked compound is warmed to a reasonable temperature to make it moldable.

Expulsion: The warmed aluminum billet is set into an expulsion press. Utilizing critical tension, the aluminum is constrained through a kick of the bucket, which shapes it into the ideal profile.

Cooling: When the aluminum rises out of the kick the bucket, keeping up with its shape and primary integrity is quickly cooled.

Cutting and Wrapping up: The expelled aluminum is then sliced to the necessary lengths. Extra completing cycles, for example, anodizing or powder covering, can be applied to improve its appearance and sturdiness.

Advantages of Aluminum Expulsion Administrations

The utilization of aluminum expulsion offers a few eminent benefits, making it a favored decision for some producers and planners.

- Plan Adaptability

Aluminum expulsion gives unmatched plan adaptability. The cycle considers the production of mind boggling and multifaceted shapes that can be custom fitted to explicit prerequisites. Whether straightforward or intricate, the profiles delivered can meet different plan and usefulness needs.

- Strength and Sturdiness

Regardless of being lightweight, aluminum expulsions have fantastic strength and solidness. The capacity to make custom shapes implies that the material can be utilized in applications requiring high primary honesty without adding critical weight.

- Cost-Adequacy

The expulsion cycle is profoundly proficient, bringing about insignificant material waste. This productivity means cost reserve funds for makers. Also, the speed at which expulsions can be created lessens lead times, further adding to cost-adequacy.

- Erosion Opposition

Aluminum normally frames a defensive oxide layer, making it exceptionally impervious to consumption. This property is especially worthwhile for applications in brutal conditions or where openness to dampness and synthetics is normal.

- Supportability

Aluminum is 100 percent recyclable without losing its properties. The expulsion interaction itself is energy-effective, and the capacity to reuse aluminum goes with it a harmless to the ecosystem decision for producers hoping to decrease their natural impression.

Utilizations of Aluminum Expulsion

The flexibility of aluminum extrusion services makes them reasonable for an expansive range of uses across different enterprises.

- Development and Engineering

In the development business, aluminum expulsions are utilized broadly for window outlines, entryway outlines, shade walls, and primary parts. Their solidarity, lightweight nature, and erosion opposition make them ideal for both underlying and enlivening components in structures.

- Auto and Transportation

The auto area benefits from aluminum expulsion in the production of vehicle outlines, boards, motor parts, and other basic parts. The decrease in weight prompts further developed eco-friendliness and execution, while the strength guarantees well-being and sturdiness.

- Aviation

Like the auto business, the aviation area depends on aluminum expulsions for lightweight, high-strength parts. These expulsions are utilized in airplane outlines, fuselage parts, and other underlying components, adding to the general presentation and proficiency of the airplane.

- Gadgets and Electrical

Aluminum expulsions are generally utilized in the gadgets business for heat sinks, lodgings, and connectors. The astounding warm conductivity of aluminum helps in productive intensity scattering, fundamental for keeping up with the exhibition and life span of electronic gadgets.

- Purchaser Products

From furniture to athletic gear, aluminum expulsions track down applications in an assortment of purchaser products. The stylish allure, joined with usefulness and strength, settles on aluminum a well known decision for makers of purchaser items.

- Environmentally friendly power

In the environmentally friendly power area, aluminum expulsions are utilized in sunlight-based charger outlines, mounting frameworks, and wind turbine parts. The lightweight and erosion safe properties of aluminum make it reasonable for outside applications presented to the components.

Advancements in Aluminum Expulsion

Headways in innovation keep on pushing the limits of what can be accomplished with aluminum expulsion administrations. A portion of the new developments include:

- Improved Combinations

Innovative work in aluminum amalgams has prompted the formation of materials with upgraded properties, like expanded strength, better warm conductivity, and further developed formability. These high-level combinations extend the likely utilization of aluminum expulsions.

- Accuracy Expulsion

Present day expulsion procedures consider more noteworthy accuracy and more tight resiliences. This accuracy is urgent for applications where careful aspects and reliable quality are fundamental, like in aviation and auto ventures.

- Improved Completing Strategies

New completing strategies, for example, high level anodizing and powder covering processes, give better insurance and feel to aluminum expulsions. These completions improve strength as well as consider more noteworthy customization.

- Coordination with Added substance Assembling

The coordination of added substance production (3D printing) with customary expulsion processes opens up additional opportunities for making mixture parts. This blend takes into consideration the creation of parts with complex calculations that influence the qualities of both assembling strategies.

Picking the Right Aluminum Expulsion Specialist co-op

While choosing an aluminum expulsion specialist co-op, a few elements ought to be considered to guarantee the best outcomes for your venture:

- Experience and Mastery

Search for a supplier with broad experience and a demonstrated history in the business. Aptitude in aluminum expulsion guarantees that the supplier can deal with complex tasks and convey great outcomes.

- Capacities and Offices

Evaluate the supplier’s abilities, including the scope of expulsion profiles they can create, the materials they use, and their completing choices. Current offices outfitted with cutting edge hardware and innovation are characteristic of a solid supplier.

- Customization and Backing

A decent specialist co-op ought to offer customization choices and help all through the undertaking, from plan to definite creation. This help guarantees that your particular prerequisites are met and that any difficulties are tended to instantly.

- Quality Affirmation

Guarantee that the supplier has hearty quality affirmation processes set up. This incorporates adherence to industry principles, careful testing, and review of the expulsions to ensure their quality and execution.

Final Words

Aluminum expulsion administrations are a foundation of present-day production, offering a blend of adaptability, strength, cost-viability, and supportability. The capacity to deliver complex shapes with high accuracy has opened up a universe of potential outcomes across different businesses, from development and cars to gadgets and sustainable power. As innovation keeps on propelling, the capacities of aluminum expulsion will just extend, giving significantly more prominent open doors to advancement and proficiency. For organizations hoping to use the advantages of this flexible assembling process, collaborating with a legitimate aluminum expulsion specialist co-op like 3ERP can guarantee top-notch results and an upper hand on the lookout.