The Emergence of Automation in CNC Machining

Automation is swiftly reshaping the landscape of CNC machining. By integrating software and robotics manufacturers are achieving levels of accuracy and efficiency. Automation allows CNC machines to function with involvement reducing errors and boosting productivity significantly. Recent research indicates that this shift is set to continue, with an impact on manufacturing sectors. The ability to automate machining processes means manufacturers can now produce top quality components at a pace and with greater efficiency than ever before. This transformation isn’t about speed; it’s also about attaining a level of precision.

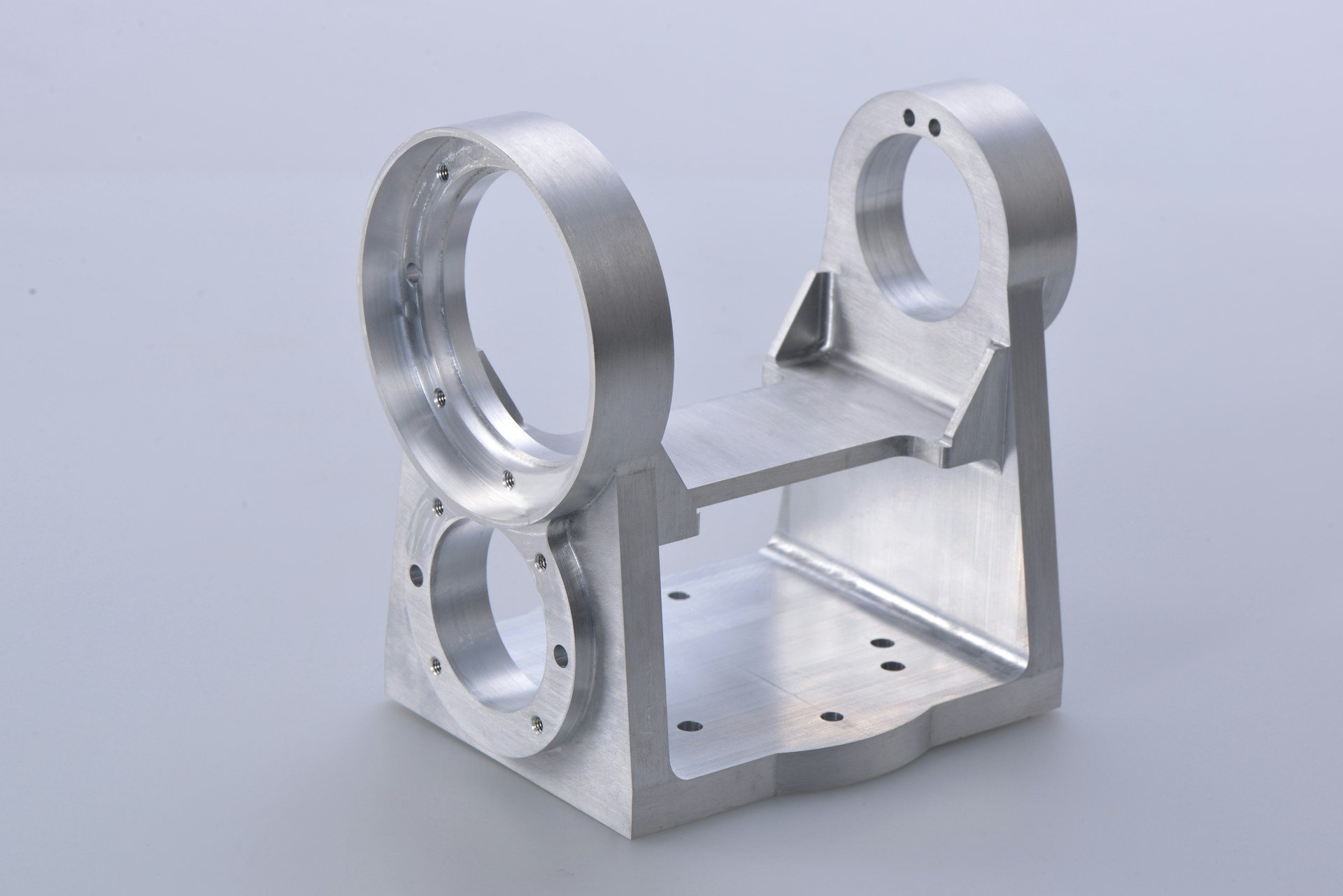

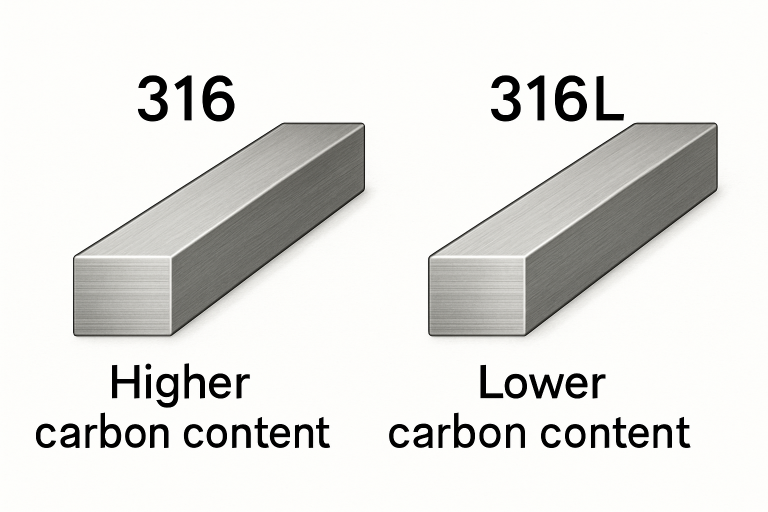

Advancements in Material Science

The evolution of materials is transforming the realm of CNC machining. From composites to high performance alloys these cutting edge materials offer durability, reduced weight and enhanced performance. A crucial element, in automated CNC systems is the availability of precise parts that facilitate operation and maintenance. For example the aerospace industry has long depended on materials to meet safety and performance standards. By using materials manufacturers can create parts that are not just stronger but also much lighter leading to improved fuel efficiency overall. Experts point out that integrating these materials results, in adaptable machining methods. Titanium and carbon fiber composites are now being utilized to make lightweight components. This transition to cutting edge materials allows industries to explore opportunities and uses for CNC machined parts, with Acu-Rite parts playing a key role in ensuring accuracy and reliability.

Enhancements in Computer Aided Manufacturing (CAM) Software

CAM software is evolving with features providing machinists with enhanced tools and a user friendly interface. Modern CAM software streamlines the design process while improving the precision of machining tasks. For instance, the latest CAM software offers real time simulation capabilities enabling machinists to visualize the machining process. This feature helps in pinpointing issues and optimizing tool paths for efficiency gains. Consequently, manufacturers can handle projects seamlessly. The precise simulation and planning of machining operations reduce the likelihood of errors. Ensure that the final product meets specifications. The advancements, in CAM software not simplify processes but also push the boundaries of CNC machining capabilities forward.

Real-World Applications

In industries, like aerospace, automotive and medical devices CNC machining plays a role. For example, CNC machines are crucial in crafting airplane parts with precision to meet industry standards. Even small deviations from design specifications can have impacts on the aerospace sector. CNC machining ensures that each component meets safety and operational requirements. The automotive sector benefits greatly from CNC machining by creating parts that improve vehicle performance and safety. Whether its engine components or complex dashboard assemblies CNC machines produce visually appealing parts. Similarly the medical field relies on CNC machining to produce instruments and implants essential for care. The accuracy and consistency of CNC machined parts make them indispensable in applications where precision’s key.

Reducing Waste with CNC Machining

CNC machining is advantageous in minimizing waste due, to its precision manufacturing capabilities. By using materials it reduces scrap generation and enhances overall efficiency. This not cuts down costs. Also promotes sustainable manufacturing practices. In contrast traditional machining methods often lead to material wastage caused by errors and inaccuracies. With CNC machining following instructions only the necessary material is removed, reducing waste significantly.

Moreover the ability to create parts in a setup reduces the need, for multiple machining processes resulting in less material wastage. This manufacturing approach not saves costs. Also benefits the environment by decreasing raw material consumption and its environmental footprint.

The Influence of IoT on CNC Machinery

The Internet of Things (IoT) is playing a role in CNC machining. By incorporating technologies CNC machines can interact with devices allowing for real time monitoring and predictive maintenance. This connectivity reduces downtime. Enhances manufacturing productivity. CNC machines with capabilities can monitor temperature, vibration and tool wear to identify issues on and prevent equipment failures. Through maintenance using technology maintenance tasks can be scheduled more effectively minimizing unexpected downtime and extending the lifespan of CNC machinery. The shift toward connected machining operations is revolutionizing how manufacturers approach maintenance and operational efficiency. Instant data collection and analysis from CNC machines provide insights that can improve production processes and increase efficiency.

Insights from Industry Experts on Future Developments

Experts, in the industry foresee that continuous innovation and integration of technologies will shape the future of CNC machining. With the progress, in automation, material science and IoT the manufacturing industry is set for growth and transformation. Experts believe that combining these technologies will result in CNC machines capable of accomplishing tasks that were previously thought to be unachievable. The upcoming era of CNC machining is expected to be shaped by the integration of intelligence and machine learning. These advancements hold the potential to further enhance the capabilities of CNC machines making them more precise and efficient. Manufacturers need to keep of the trends and innovations as the sector evolves to stay competitive and seize new opportunities.

Insights from Research Data

Recent findings from research studies highlight the increasing efficiency and accuracy of CNC machining systems. These reports emphasize the advantages of embracing cutting edge technologies to enhance machining processes and drive industry advancement. Studies indicate that manufacturers who invest in state of the art CNC machining technologies are experiencing enhancements in productivity and quality. By staying informed about progressions and incorporating novel technologies manufacturers can foster innovation within the realm of CNC machining. There are prospects for innovation and expansion, in the landscape of CNC machining offering a promising outlook. It will be intriguing to observe how these advancements shape the future of manufacturing and impact the economy as the industry moves forward.