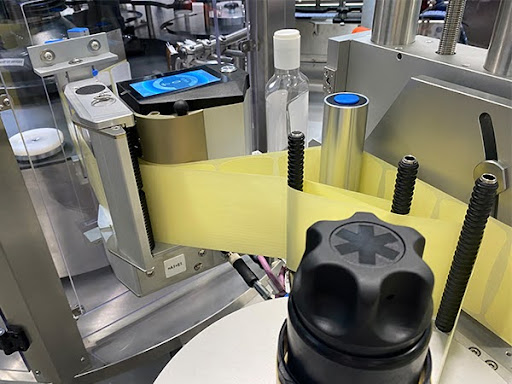

Labeling occupies the focus position in the production processes taking place in manufacturing and packaging companies and enterprises dealing with product packaging. Focusing on the types of labeling machines, one machine is surely the most popular, the wrap-around label machine. This guide will teach you more about wrap-around labeling technology, its kind, and its use throughout various industries.

Identifying Wrap Around Labeling Technology

The way wrap around labeling is structured:

The wrap-around labeling refers to labeling where a single label is applied in a circular style that goes around the whole periphery of the tubular product. This is a job that is typically performed by the wrap-around label machine; this machine is designed in a way that the label is placed around any container shape or size with maximum ease.

The wrap-around labeling process typically involves: The wrap-around labeling process typically involves:

Product Infeed: Raw materials are conveyed to the machine in the form of products that need to be packed.

Label Application: Adhesive labels are used in this kind, taken from a roll and attached to the product while in motion.

Seamless Wrapping: The machine then covers the label around the product firmly such that there are no air bubbles or misalignment.

Product Outfeed: The labeled products are, thereby, expelled from the machine and are, therefore, ready for packaging or shipping.

Various models of wrap around label machines

Wrap-around label machines can be available in different models to suit the user’s specific production line. Awareness of these types will assist a business in selecting the proper equipment suited for the intended use.

Automatic wrap around label machines

Description: These are stand-alone machines and do not require operator interference when it comes to labels that need to be produced several at a time.

Advantages: Increased operating speed, lower costs as compared to human labor, and uniformity in the label appearance.

Applications: Ideally applicable for large production companies that deal with food production processes, medicine production, and other production companies.

Semi-automatic label wrapping or banding machines

Description: These types of machines can be partially automated, but they are not completely automatic; therefore they are well suited to small-scale production runs as well as specific uses

.Advantages: More control over the labeling process and bringing more appeals to the market for lower initial investments.

Applications: Ideal for companies with limited sales or special products and services that need some modifications regarding the ordering process.

Rotary wrap around is a type of label machine used in industry, particularly in the production of canned goods, beverages, and other consumable products.

Rotary Wrap Around Label Machines

- Description: Continuous operation is also made possible through the use of rotary machines that employ a rotating carousel on which labels are put to the products.

- Advantages: Ability to process thin gauges and intricate shapes and acceptable capability for processing complex shapes of products irrespective of their sizes.

- Applications: Most suitable for organizations that frequently need to change labels or have many products.

Applications Across Industries

Food and Beverage Industry

The stand that presentation and compliance take in food and beverage manufacturing is significant. Wrap around labels are commonly used for labeling bottles, cans, and jars which gives the possibility to brand the object on every side. Labels are applied accurately and promptly by the machines protecting the quality and safety of the foods.

Pharmaceutical Industry

In the pharmaceutical industry, assembling is concerned with a very high level of accuracy and standards.

In this sector, the labeling part is sensitive due to the compliance with various regulations as well as the safety of patients. (Pharmaceutical) wrap around labeling machines most appropriate for these applications are pharmaceutical wrap-around labelers as these machines are suitable for different kinds of containers such as vials, bottles, and syringes.

This means that patient-related information such as dosage instructions and the dates when the medicines are set to expire can be easily accessed.

Consumer Goods and Cosmetics

Hence, in the consumer goods and cosmetics industry, brand identity and product appearance are crucial. As a result, wrap-around label machines enable easy application of labels that can improve the aesthetic appeal of the product hence improving consumers’ appeal.

These machines in packaging can work on a broad range of packaging materials such as glass, plastic, as well as metal.

Other Industries

Other industries that include the use of wrap-around labeling machines include chemicals, automotive industries, and electronics, where correctness is crucial when it comes to labeling of their commodities.

Features of Wrap Around Label Machines

Efficiency and Speed

The wrap-around label machines are specially developed for high-speed application and these machines could be easily adaptable in a fast manufacturing environment. When the labeling process is automated, the business organization is in a position to produce high rates with minimal or no time wastage.

Precision and Consistency

The technology used in the wrap-around labeling systems guarantees the application of the labels in uniformity thus minimizing the mistakes made on the brands’ images. Such a level of accuracy is especially critical in industries that work under high levels of regulation, such as the production of medicine and pharmaceuticals since wrong labeling is disastrous.

Cost-Effectiveness

Thus, even though the costs of purchasing a wrap-around label machine may be high at one given time, the overall cost of using the machine for labeling ultimately proves to be highly cost-effective. These machines eliminate the need for employing manpower, cut down on the amount of material used in the process, and optimize direct labor productivity.

The basics of wrap around label machines: how to choose the right one.

When selecting a wrap-around label machine, several factors should be considered:

Production Volume: First, the amount of production that your business model is capable of producing should be defined.

Product Specifications: Think about the size and the form of the products to be labeled.

Label Material: Check whether the type of label material on use is compatible with the particular machine being used.

Ease of Maintenance: This can be easily determined by searching for machines with simple and easy controls; the machines should not be hard to maintain.

Investigations of Future Trends Concerning the Application of Wrap Around Labeling Technology

Technological Advancements

The developments in the machines are giving better and more flexible solutions for wrap-around labeling. Characteristics like digital printing, laser engraving, and machine learning are already embedded with labeling machines displaying more precision and adaptability.

Sustainability and Eco-Friendly Options

In labeling technology, the sustainability aspect is sluggish but surely it’s an important concern. Wrapping label machines are introduced to run sustainable papers to eliminate waste of papers in the world.

Automation and its Integration with the Internet of Things

One innovation that has recently occurred and unites the wrap-around label machines is the Internet of Things. Sensors and connectivity of smart machines ensure condition-based monitoring, prediction of machine faults, real-time monitoring, and integration.

Conclusion

Wrap-around label machines are widely used in contemporary production and packaging lines. For this reason, they prove useful in different sectors: food and beverage, the production of pharmaceuticals, among others owing to the value they create by affixing labels perfectly.

Thus, by examining the variations of the wrap-around labeling machines and their uses, the readers who make up today’s businesses can make proper conclusions that promote their overall success in the production field.